What is the Most Durable Grating Tread Material Available

2025-12-03

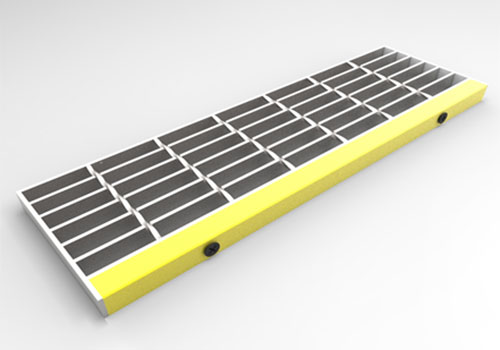

Have you ever stood on a factory floor, looked down at the worn, slick surface underfoot, and wondered, “What is the most durable grating tread material I can find?” If so, you’re not alone. For engineers, facility managers, and safety officers, finding a solution that stands up to extreme wear, corrosive chemicals, and punishing impacts is a constant challenge. The wrong choice leads to costly replacements, safety hazards, and downtime. That’s precisely why, at Tank, we’ve dedicated years to engineering a superior answer. We believe the quest for the ultimate grating tread ends with a deep understanding of material science and real-world performance.

Why Should You Care About Grating Tread Durability

Durability isn’t just about longevity; it’s about operational safety and total cost of ownership. A failing grating tread creates slip-and-fall risks, fails under heavy loads, and can corrode quickly in harsh environments. I’ve spoken with countless clients who were frustrated by products that promised strength but delivered disappointment. They needed a grating tread that could handle forklift traffic, resist oil and chemical spills, and endure temperature swings—all without frequent maintenance. This widespread need drove our innovation at Tank.

What Makes Tank’s FRP Grating Tread the Superior Choice

After extensive testing, we determined that Fiberglass Reinforced Plastic (FRP) offers the best combination of properties for the most demanding applications. But not all FRP is created equal. Tank’s proprietary formulation and manufacturing process create a grating tread that outperforms alternatives like steel, aluminum, or standard composites. Here’s a breakdown of what sets our material apart:

-

Inherent Corrosion Resistance: Immune to rust and resistant to a vast range of chemicals, acids, and alkalis.

-

High Strength-to-Weight Ratio: Exceptionally strong while being lightweight, easing installation and reducing structural support needs.

-

Non-Conductive & Non-Sparking: Essential for electrical safety and hazardous environments.

-

Slip-Resistant Surface: Molded-in grit surface provides superior traction, even when wet or oily.

-

Low Maintenance: Requires no painting or coatings and is easily cleaned with water.

How Do the Technical Specifications Translate to Real-World Performance

Let’s move beyond features and look at the hard data. The following table details the key parameters of our flagship Tank DuraGrate Tread, illustrating why it is engineered for unmatched durability.

| Property | Tank DuraGrate Tread Specification | Industry Standard FRP | Real-World Benefit |

|---|---|---|---|

| Fiberglass Content | 65% by weight | 50-55% | Higher structural integrity and load-bearing capacity. |

| Resin System | High-Performance Isophthalic/Veova | General Purpose Orthophthalic | Superior corrosion resistance and UV stability. |

| Barcol Hardness | 50+ | 40-45 | Exceptional resistance to impact and surface abrasion. |

| Deflection at Max Load | < L/200 | L/180 | Minimal flex under stress for a solid, secure feel. |

| Fire Retardancy | ASTM E-84 Class 1 Rating | Class 2 or Unrated | Enhanced safety for indoor and critical infrastructure. |

This data isn’t just numbers on a sheet. It means our grating tread will last years longer on a chemical plant walkway, support heavier loads in a wastewater treatment facility, and provide a safer surface on an offshore platform. The investment in a Tank solution pays dividends through decades of reliable, worry-free service.

Are You Ready to Solve Your Flooring Challenges for Good

Choosing the right grating tread material is a critical decision that impacts safety, budget, and operational efficiency for years to come. You don’t have to settle for materials that degrade, rust, or become unsafe. The evidence is clear: a high-performance FRP tread, specifically engineered like the one from Tank, offers the most durable solution available.

Stop wondering about durability and start experiencing it. We invite you to contact us today with the specifics of your project—whether it’s for a new build or a critical replacement. Let our team provide you with a detailed quote and technical support to ensure you get the perfect, long-lasting flooring solution. Reach out now and let’s build something that endures.