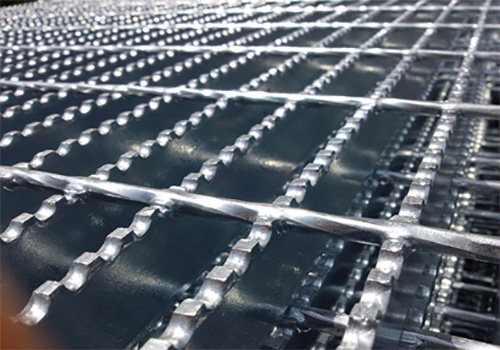

Steel Grating

Steel Grating

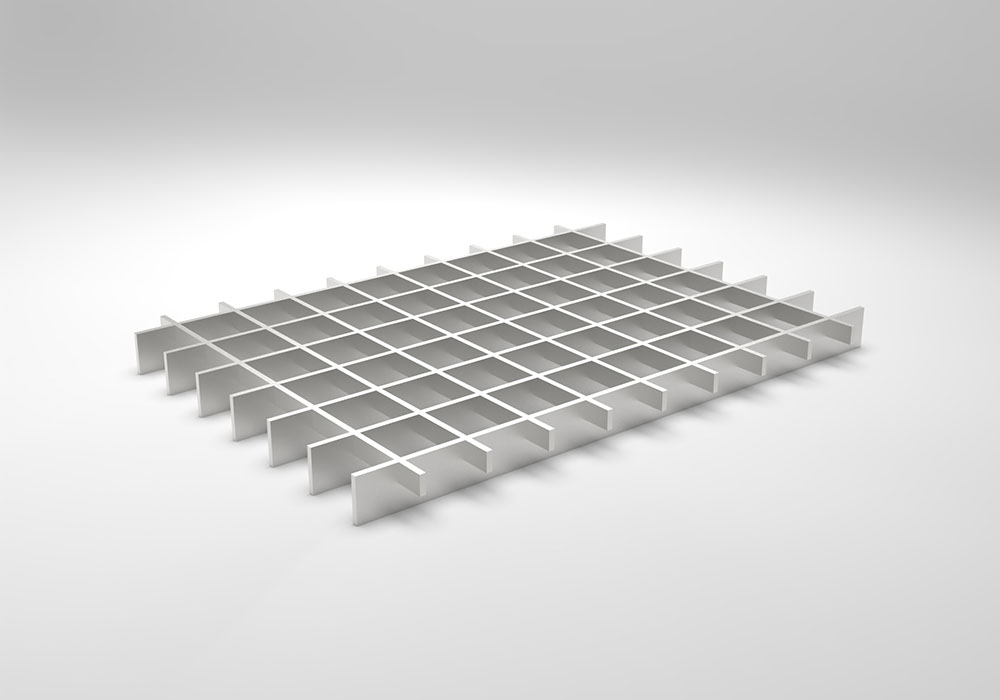

Steel grating is an open steel structural component composed of load-bearing flat steel and horizontal bars that are orthogonally combined at a certain distance and fixed by welding or locking. It is divided into welded steel grating and locked steel grating according to different manufacturing methods.

Application of steel grating:

Industrial buildings: offshore wind platforms, warehouses and coating production lines in automobile factories, large logistics sorting centers, power plants, chemical plants, electronic component factories, polycrystalline silicon factories, etc

Civil buildings: garden walkways, airport corridors, shopping center walls, and various types of building drainage ditch covers.

The bearing strength of steel grating is very important because it is usually 1 meter to hundreds of meters away from the lower layer or ground. You can find the figure of steel grating on the top of skyscrapers. Despite the highly competitive market and significant cost pressures, 4.0 Industrial Company adheres to the principle of quality first. At the same time, we provide customers with a complete set of services and reasonable suggestions from the selection, design, and installation of steel grating to avoid safety hazards caused by these reasons.

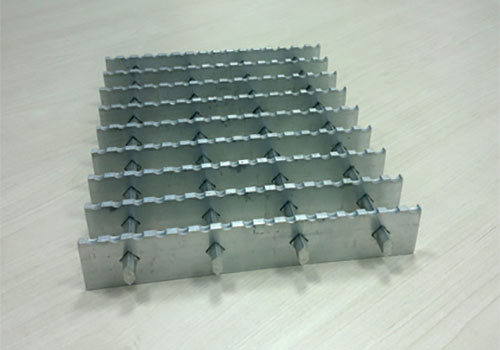

Press-locked Steel Grating

Press-locked Steel Grating

4.0 Industrial Company is one of the few manufacturers that can produce genuine locking steel grating with DIN24537 in China. Due to the significant differences in production technology from those used for pressure welding gratings, and the ability to produce a wider range of products. In addition, the horizontal bars of the locking steel grating also provide load-bearing capacity and transfer the force of a single force point to other load-bearing bars involved in the entire horizontal bar, so the locking steel grating is more economical under same pressure. The locking steel grating also provides a safer visual experience.

Friendly reminder: The process of press-locked steel grating is to lock the steel grating through the interference fit force of the steel. There are some products on the market that look the same, but they actually fix the load-bearing flat steel and crossbar through manual welding point by point. This type of product not only lacks straightness, but also has an impact on aesthetics. What's more serious is that its welding points are manually operated, and there are a lot of intersection points, so there are phenomena of missed welding and unstable welding, Very prone to safety accidents.

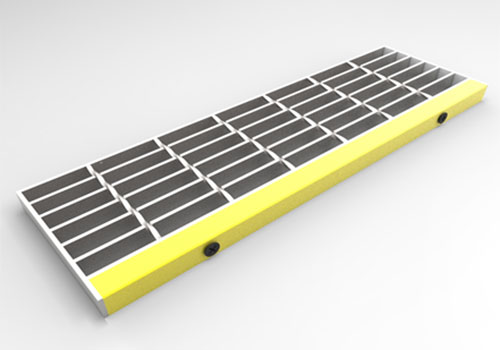

Grating Tread

Grating Tread

Grating Tread is used in many architectural, commercial, and industrial applications, 4.0 steel industry's durable, safe, and slip resistant stair treads are available in many styles:

Pattern board anti slip strip (globally applicable, the most common style); Punched plate anti slip strip (commonly used on offshore platforms and chemical platforms); Concave flat steel anti slip strip (popular in Japan and South Korea); Diamond anti slip strip (also known as grinding anti slip strip, preferred by owners in Australia and Europe). We can provide more styles of grating tread products to cater to the different preferences of the final owner.

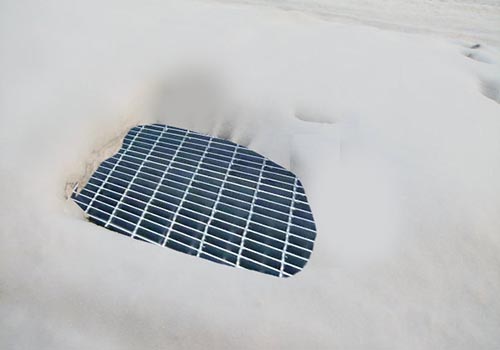

Stainless Ditch Cover

Stainless Ditch Cover

Stainless Ditch Covers are an excellent option that will work for any facility and provide you with a clean, strong, and reliable design. Here are just a few of the benefits of going with a stainless steel drain grate.

More hygienic

Stainless steel is a nonporous material, making it smooth and easy to clean. This means that cleaning a stainless steel grate is much easier, and there is no chance of waste getting stuck in pores or ridges. The first, and possibly biggest, benefit to going with a stainless steel trench/ditch drain is the hygienic and sanitary factor.

More aesthetically pleasing

We often see cast iron, galvanized or various colored fiberglass trench covers. But stainless steel trench covers can give us a better texture. Stainless steel trench cover plates can improve the grade of buildings.

We can provide customers with three surface treatment methods:

Physical drawing, due to its smooth appearance, is often used in shopping malls, hotels, parks, high-end swimming pools, etc.

Electrolytic chemical polishing, with a smooth and bright surface, commonly used in food factories, pharmaceutical factories, etc.

Acid pickling and passivization, used in areas with low appearance requirements, commonly used in chemical plants, automotive painting production workshops, seaside factories, etc.

Of course, we can also produce conventional galvanized trench covers.

Featured Products

About Us

4.0 (Taizhou) Steel Industry is founded by a professional team with rich experience in developing, designing, producing and selling steel gratings and handrails.We have three kinds of products: Gratings (including stainless steel grating, press locked gratings, low temperature resistant plate, tread and so on); Industry handrails; Aluminum gratings.

New Products

News

Petrochemical Projects

Tank Steel Grating is widely used in petrochemical industry's environmental protection field. Our products address the needs of steel grating from SINOPEC, CNPC, Madura FPU marine gasoline tankers, Yihai Kerry factories, etc. We're skilled at manufacturing grating products with special diameters, which satisfies client needs.

Offshore Wind Power Projects

In recent years, more and more projects on Offshore Wind Power are proceeded by Chinese enterprises and they start to apply Jacket platform in their projects. For more corrosive sea-water environment, Tank Steel Grating adopts the high-grade galvanized anti-corrosion grating at 150μm (average value) in replace of the galvanized anti-corrosion grating at 120μm (average value).

Chinese Fuzhou City Forest Pavement

Chinese Fuzhou City Forest Pavement, at a full length of 19 kilometers, flies over Chinese Fuzhou Jinniushan Park. This pavement is awarded "International Architecture" by Chicago Athenaeum (Museum of Architecture and Design) and European Centre for Architecture Art Design and Urban Studies.