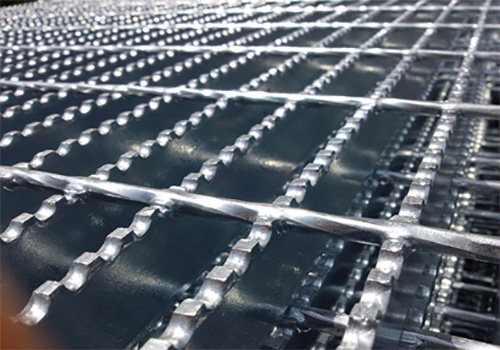

Stainless Ditch Cover

Stainless ditch cover drain grates are an excellent option that will work for any facility and provide you with a clean, strong, and reliable design.

Send Inquiry

Stainless ditch cover_stainless trench cover_stainless drain cover:

Stainless ditch cover drain grates are an excellent option that will work for any facility and provide you with a clean, strong, and reliable design.

Stainless steel is a nonporous material, making it smooth and easy to clean. This means that cleaning a stainless steel grate is much easier, and there is no chance of waste getting stuck in pores or ridges.The first, and possibly biggest, benefit to going with a stainless steel trench/ditch drain is the hygienic and sanitary factor.

Tank Ditch Cover are designed to service applications subject to ditch、cable trench、 ventilation shaft 、Light wells ,inspection well and so on. Compared with normal grating,the end bar and each bearing bar must be welded together. The two side must be welded of bearing bar,when heavy truck will go over the cover.

Marks:

e.g. GT(G325/30/50G)

GT - Cover type; 30 - Grating type

Types (GT, GM & GU):

|

|

|

|

I. GT Anchor are welded with angle steel and embed in concrete floor. Application: Sea Port,Highway,Plants Floor and so on.Two grates are connected by bolt to avoid jumping,when heavy truck rolled through grate. |

II. GM Anchor are welded with angle steel and embed in concrete floor. The grate is connected to the angle steel frame. Application: Park ,Square,Residence community and so on. GM grate are designed to avoid loss and stolen ,GM grate prevent person fall well. |

III. GU The flip angle steel are weld with grate end bar together. Application: The nosing of concrete ditch or well do not need to be cut. GU grate are design for person walk or light car. |

Welding details:

|

|

|

|

Products cases: