China Trench Drain Grille Cover Manufacturer, Supplier, Factory

It is a great way to further improve our items and repair. Our mission would be to develop resourceful items to clients with a superior encounter for Trench Drain Grille Cover,Stainless Trench Cover,Grating Ditch Cover,Grating Drain Cover, Our hugely specialized process eliminates the component failure and offers our customers unvarying high quality, allowing us to control cost, plan capacity and maintain consistent on time delivery.

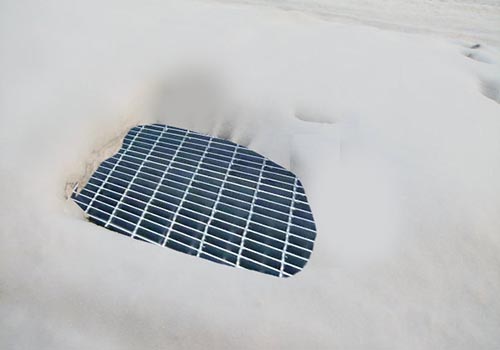

Trench Drain Grille Cover, During the development, our company has built a well-known brand. It is well highly acclaimed by our customers. OEM and ODM are accepted. We've been looking forward to customers from all over the world to join us to a wild cooperation.

Hot Products

Offshore Grating

Tank is one of leading China Offshore Grating manufacturers, suppliers and exporters.Swag Locked Steel Grating

Being a proficient manufacturer, Tank aims to offer you Swag Locked Steel Grating. We promise to provide you with the best after-sale support and prompt delivery.Pressure Locked Steel Grating

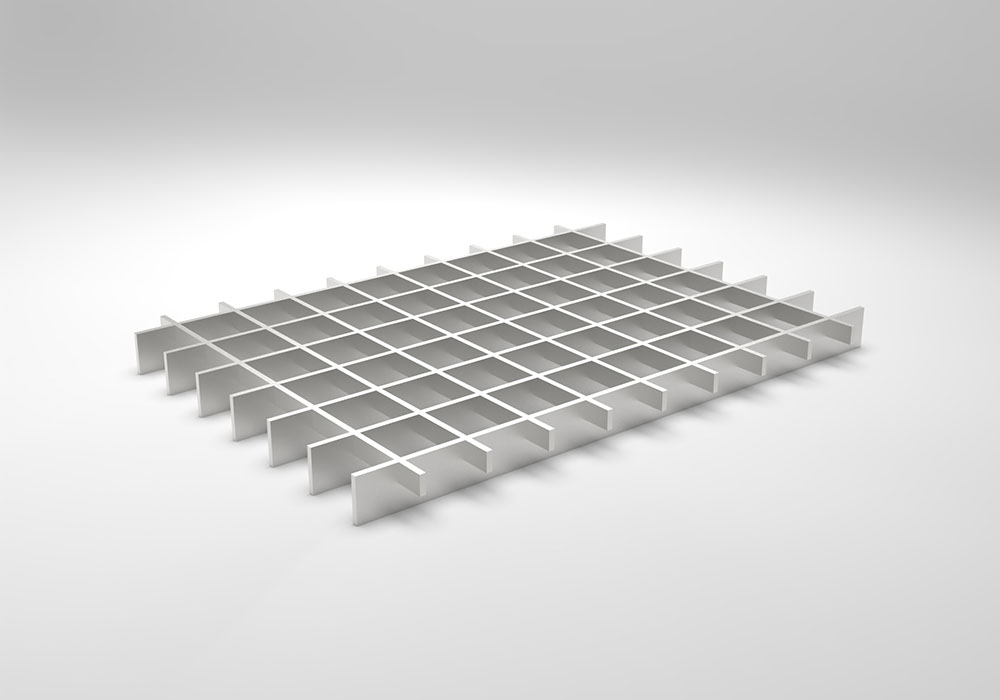

Pressure locked steel grating consist of parallel load-bearing bars. During the manufacturing process, the load-bearing bars are notched in advance, and the cross bars are pressed into the notches using a large press machine of more than 300 tons, and finally welded around the edges.Industrial Rail

Industrial Rail is also known as ball joint railing/Barriers, ball joint handrails have advantages such as beautiful appearance, easy installation, durability, and good anti-corrosion performance after hot-dip galvanizing.Plank Grate

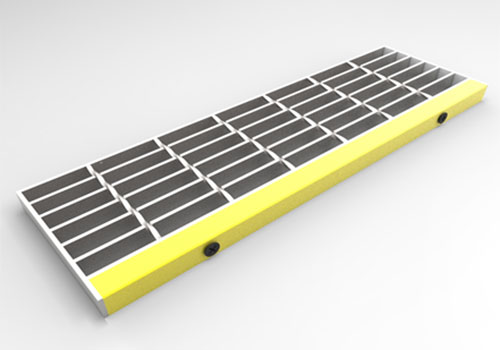

Plank Grate is also know as safety grating which manufactured by cold stamping and forming carbon steel, aluminum, or stainless steel into a one piece, modular plank, or sheet with distinct walking surfaces.Shelf Grating

Steel shelf grating, especially press locked grating, is widely used in the racking industry. The use of lightweight press locked grating can effectively reduce the weight of the rack.