China Grating Drain Cover Manufacturer, Supplier, Factory

We usually believe that one's character decides products' high quality, the details decides products' excellent ,with the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for Grating Drain Cover,Stainless Trench Cover,Grating Ditch Cover,Trench Drain Grille Cover, Welcome to speak to us should you be intrigued inside our solution, we're going to provide you with a surprice for Qulity and Price tag.

Grating Drain Cover, Our goods are produced with the best raw materials. Every moment, we constantly improve the production programme. In order to ensure better quality and service, we have been focusing on the production process. We have now got high praise by partner. We're looking forward to establishing business relationship with you.

Hot Products

Swag Locked Steel Grating

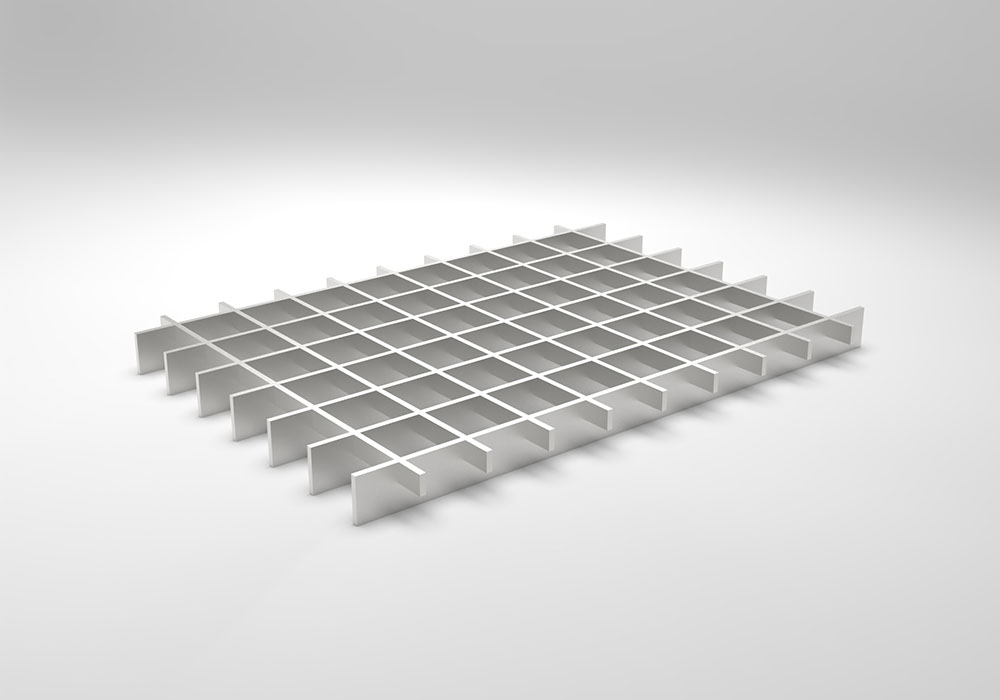

Being a proficient manufacturer, Tank aims to offer you Swag Locked Steel Grating. We promise to provide you with the best after-sale support and prompt delivery.Pressure Locked Steel Grating

Pressure locked steel grating consist of parallel load-bearing bars. During the manufacturing process, the load-bearing bars are notched in advance, and the cross bars are pressed into the notches using a large press machine of more than 300 tons, and finally welded around the edges.Stainless Ditch Cover

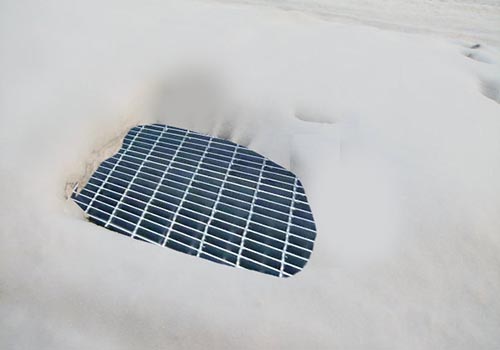

Stainless ditch cover drain grates are an excellent option that will work for any facility and provide you with a clean, strong, and reliable design.Industrial Rail

Industrial Rail is also known as ball joint railing/Barriers, ball joint handrails have advantages such as beautiful appearance, easy installation, durability, and good anti-corrosion performance after hot-dip galvanizing.Plank Grate

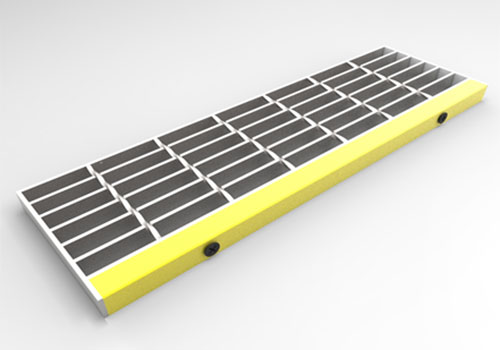

Plank Grate is also know as safety grating which manufactured by cold stamping and forming carbon steel, aluminum, or stainless steel into a one piece, modular plank, or sheet with distinct walking surfaces.Heavy Locked Grating

This is a heavy locked grating with a deeper or thicker bearing bar. The size of the cross bar is also adjusted accordingly.